|

|||

|

|

|||

|

Page Title:

Chapter 3. DIRECT SUPPORT MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM 11-6125-259-30

CHAPTER 3

DIRECT SUPPORT MAINTENANCE INSTRUCTIONS

Section 1. GENERAL

3-1. Voltage Measurements

CAUTION

When performing d below, make sure

Table 3-1 lists the voltages that can be expected in

component, pine and printed wiring on

the inverter. Perform the instructions in this

A7 component assembly (17) do not touch

paragraph only when necessary to check these

standard voltages.

chassis ground; do not damage in-

terconnecting wiring.

WARNING

d. Carefully lay back upper end of A7 component

High voltages and currents are present

assembly (17) 90 degrees over onto work bench.

on disassembled inverter when it is

Avoid strain on interconnecting wiring. A6 com-

energized. Do not touch any exposed

ponent assembly (16) is now accessible.

wiring or any metal point within the

e. Connect inverter to test fixture as shown in

inverter: Lethal shock could result.

a. Partially disassemble inverter (para 3-0 a and

and S22 to up position (83.3 VA).

b.) gains access to A1, A4 and A5 modules (6 and 34,

f. Set UNIT PWR switch S6 to ON position and

fig. 3-21) and A7 component assembly (17).

apply 28 1 vdc input power to inverter.

b. Loosen A7 component assembly (17) by

removing six screws (20), six lockwashers (21) and

voltmeter), measure the voltages as prescribed in

six flat washers (22).

c. Place inverter on work bench with front side

3-15, 3-17 and 3-18 for location of referenced pins.

down.

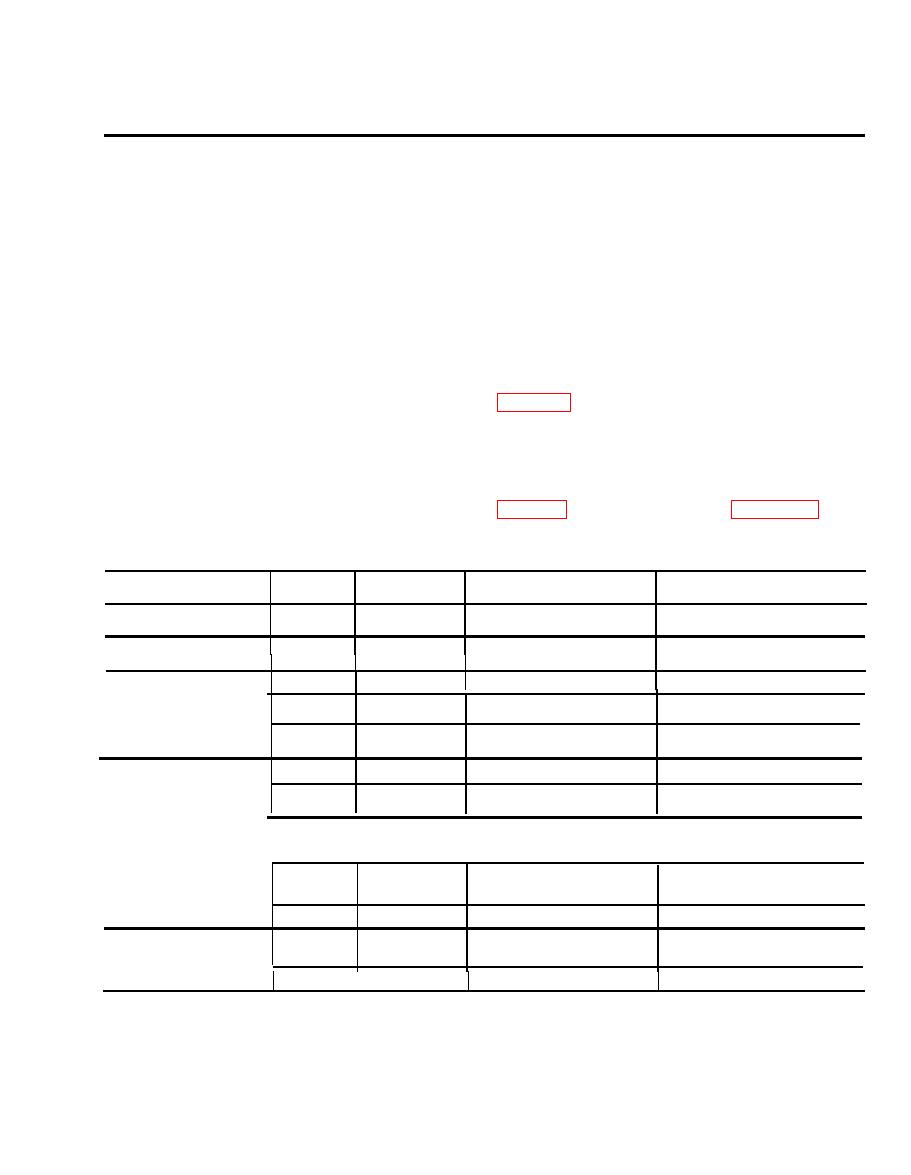

Table 9-1 Voltage Measurement

TO

FROM

VOLTS DC

REMARKS

ASSEMBLY

PIN

PIN

A1, EMI

Module

1(+)

l0(-)

27 to 29

A4, Power

Caps and Drive

5(+)

6(-)

37 to 41

A5, Output

13(+)

14(-)

23.0 to 27.0

Filter and

12(+)

13.99 to 14.01

14(-)

Bias Regulator

2(+)

14(-)

4.5 to 4.9

1(+)

4.5 to 5.5

7(-)

5(+)

7(-)

14.5 to 15.5

I

I

I

I

A6, Logic

6(+)

7(-)

4.3 to 4.7

With A output overloaded, see

Note 1.

6(+)

7(-)

9.8 to 10.2

With A output short-circuited,

see Note 2.

TP1(+)

7(-)

3.995 to 4.005

A7, Component

1+)

4(-)

14.5 to 15.5

Assembly, Boost

r

5(+)

4(-)

4.5 to 5.5

Regulator

Note1. This overload condition is obtained by setting switches S1, S2, S3, S4 and S5 (see fig. 3-1) to the up position. Return swit.

ches to down position after taking measurement.

Note 2. This short circuit condition in obtained by setting switch S10 (see fig. 3-1) to SHORT position. Return switch S10 to down

position after taking measurement.

3-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |