|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 11-6125-259-30

voltage shall be between 100 and 117.5 vrms.

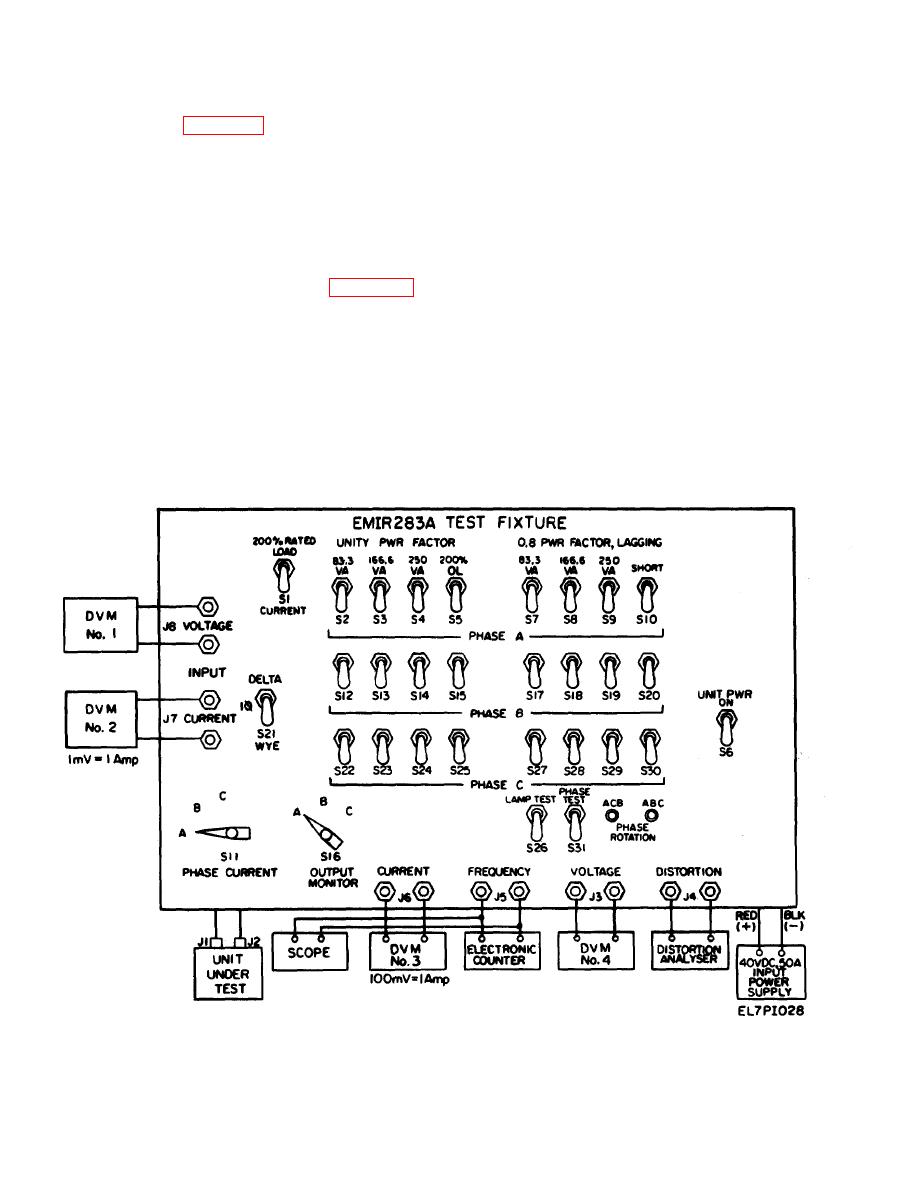

3-5. Test Setup

NOTE

connect fully assembled and closed inverter to test

The test setup and text specified the use

fixture as shown in figure 3-19 (refer to fig. FO 3-20

of four digital voltmeters for simplicity.

for test fixture schematic).

Only one digital voltmeter need be used

3-6. Procedure

and connected, in turn, to any of the four

monitoring terminals on the test fixture.

Perform the following instructions to determine

that the inverter meets operational parameters.

e. Read the percent distortion of output phase as

There are no inverter adjustments and alignments

indicated on Distortion Analyzer TS-723/A. The

nor calibration that should be performed during this

distortion shall be 5 percent maximum.

operational checkout. The initial switch positions of

the test fixture shall be as indicated on figure 3-19

on Electronic Counter AN/USM-207. The

prior to performing the instructions below.

frequency shall be between 393 and 407 Hz.

a. Set the DELTA/1WYE switch S21 to

g. Set OUTPUT MONITOR switch S16 to B and

DELTA position.

C positions respectively and at each position repeat ,

b. Set the UNIT PWR switch S6 to ON position

d through f above for the B and C outputs.

and apply 18 vdc input from the input power supply.

h. Increase the input power supply voltage to 26

c. Set OUTPUT MONITOR switch S16 to A

vdc and 29 vdc respectively, and for each input

position.

voltage repeat c through g above.

d. Read the output phase voltage indicated on

i. Set UNIT PWR switch S6 to OFF position.

Digital Voltmeter AN/USM-281 No. 4. The output

Figure 3-19. Final Test Setup.

3-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |