|

|||

|

|

|||

|

Page Title:

Input Overvoltage Adjustment (R635) |

|

||

| ||||||||||

|

|

TM 11-6125-259-30

assembly with six screws (20), six lockwashers (21)

voltmeter AN/GSM-64 No. 1.

and six flat washers (22).

f. Slowly adjust potentiometer R635 clockwise

r. Install bottom cover (18) on housing (12 with

until the oscilloscope waveform goes to 0 volts.

six screws (19).

g. Set UNIT PWR switch to S6 to down (off)

position.

3-15. Input Overvoltage Adjustment (R635)

h. Disconnect oscilloscope from inverter.

a. If not already performed, perform disassembly

and r.

procedures in paragraph 3-14 a through f.

3-16. Repair Materials

15(+) and 7(-) of component assembly A6 (fig.

3-17).

Paragraphs 8-17 through 3-19 contain procedures

c. Turn potentiometer R635 fully coun-

for using repair materials which are needed when

terclockwise.

replacing certain component parts. Table 3-3 lists

the repair materials; table 3-4 lists the component

d. connect inverter to test fixture per figures

parts and their location; pargraphs3-17 through

3-19.

e. Set UNIT PWR switch S6 to ON position and

3-19 contain instructions for preparing and using

the repair materials.

adjust input to 44 0.5 vdc as read on digital

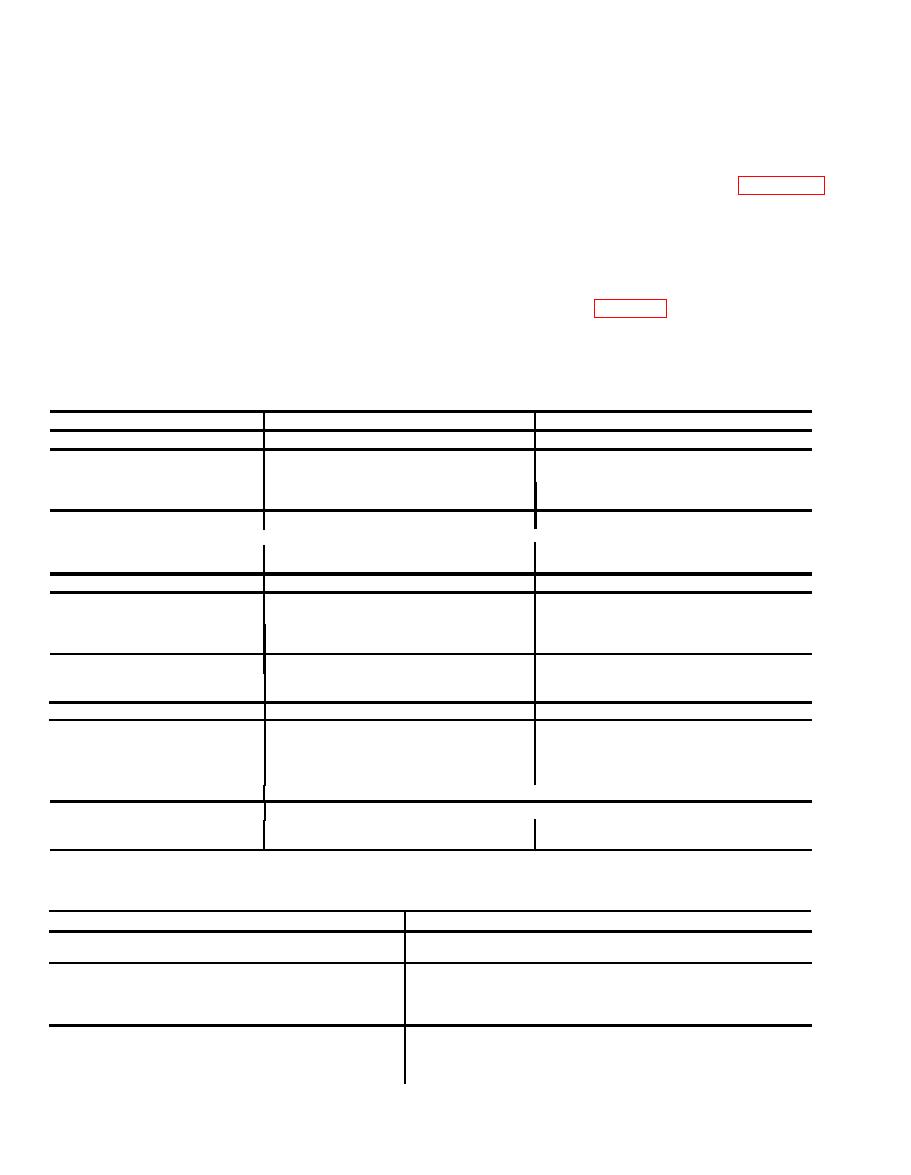

Table 3-3. Repair Materials

TYPE

MATERIAL

SOURCE

Paint

Flat Black

Commercially available

SN60-40

Kester Solder Company

4201 Wrightwood Ave.

Chicago, IL

FSCM 75295

Epocast 202

Furane Plastics, Inc.

Adhesive, Staking

5121 San Fernando Rd.

I

I

Los Angeles, CA 90039

FSCM 99384

Artist, small

Brush

Commercially available

Tuluol/Toluene

VanWaters and Rogers

Anhydrous Reagent Grade

1363 S. Bonnie Beach Pl.

Los Angeles, CA

FSCM 08455

1B31, Humiseal

Conformal Coating

Columbia Chase Corp.

Humiseal Division

Woodside, New York 11377

MIL-I-10428

Isopropyl Alcohol

Commercially available

RTV-615 A & B

General Electric

Silicone Rubber

Silicone Products Dept.

Waterford, NY 12188

FSCM 01139

RTV-910

Diluent

1G-101

Emerson & Cumings

Microballoon Sphere

Canton, MA 02021

FSCM 04552

Table 3-4 Cross Reference To Module/Component assemblies

Needing Repair Materials

REPAIR PROCEDURE AND COMPONENT PARTS

MODULE/COMPONENT ASSEMBLY

EMI MODULE Al (fig. 3-10)

Capacitors C100 through C104 and C106 through C109 are

secured with a fillet of Epocast 202 (100 parts of 202).

HIGH LEVEL BOOST MODULE A2 (fig. 3-11)

a. Capacitors C201 and C202 are secured with a fillet of

Epocast 202 (100 parts of 202).

b. A2 module is conformal coated with 1B31 (Humiseal), both

sides.

LOW LEVEL BOOST MODULE A3 (fig. 3-12

a. Capacitors C301 and C302 are secured with a fillet of

Epocast 202 (100 parts of 202).

b. A3 module is conformal coated with 1B31 (Humiseal), both

sides.

3-24

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |